We have spent almost 35 hours finding the best quiet 3D printer, especially with automatic bed leveling ability.

This comprehensive guide will help you to choose suitable noiseless 3D printers with other critical factors to consider.

Best Overall

Makerbot

- Noise below 45 DB

- Extruder quality is better

- Supports Cloudprint

Second Best

Bambulab X1C

- A Core XY 3d printer

- 500 mm per second

- Noise generation: 48.9 decibels

Budget Pick

Anycubic Vyper

- Lower noise than Creality

- Magnetic build plate

- Auto bed leveling feature

Wait a minute!

We not only considered the noise level and price but, there are plenty of ranking factors to choose the right 3D printer that is quietest.

We have taken 23 products to our testing lab and conducted a survey for 57 3d printers in total.

At the primary level, we eliminated 17 3d printers for producing sounds of more than 60DB.

We have found that Flashforge 3d printers have all the necessary qualitative factors ahead of the other two 3d printers. Bambulab & the Anycubic 3d printers are the best performer in terms of auto levelling.

We will present all of the user-friendly printers with different mainboards and bed types. Also, there will be some important technical guides on how to make 3D printers quitter.

So, let’s start.

Are 3D Printers Loud?

Due to the functionality, a 3D printer creates a lot of vibration and noise. However, we need to understand whether the noise level is beyond your tolerance level!

Can’t read a lot?

You can directly jump to our most voted quiet 3D printer>>>

Here’s a research outcome that presents – what amount of noise a 3D printer generates in DB. Also, it shows a comparison of 3D printers’ noise with other things.

Notably, the study of The University of Michigan demonstrates that the overall noise from a 3D printer is within the range of our tolerance.

Good 3D printers create on an average 35 db to 45 db sound.

However, some low-budget printers are noisier.

Moreover, due to concentration breaks and other important tasks, we may need to think about the silent 3D Printers.

We will talk about those after 15 lines.

Here’s what the research found!

| Noise Source | Average decibels (dB) |

| Leaves rustling, soft music, whisper | 30 |

| Average home noise | 40 |

| Normal conversation, background music | 60 |

| Office noise, inside car at 60 mph | 70 |

| Vacuum cleaner, average radio | 75 |

| Heavy traffic, window air conditioner, noisy restaurant, power lawn mower | 80–89 (sounds above 85 dB are harmful) |

| Subway, shouted conversation | 90–95 |

| Boom box, ATV, motorcycle | 96–100 |

| School dance | 101–105 |

| Chainsaw, leaf blower, snowmobile | 106–115 |

| Sports crowd, rock concert, loud symphony | 120–129 |

| Stock car races | 130 |

| Gun shot, siren at 100 feet | 140 |

Information Source: University of Michigan

These are the best quiet 3D printers with proven noise cancellation

These are the best silent 3D printers:

- Makerbot Replicator Plus (Best Overall)

- Bambu Lab X1 Carbon

- Falshforge Adventure 4 (Almost Silent)

- Creality Ender 3 V2 (Best in the low budget range)

- Dremel 3D40

- Anycubic Vyper

We have recommended MakerBot Replicator Plus as a Best Overall, based on these factors that helped it to be special among other 3d printers.

Besides, Creality can be an ideal device for new or intermediate users that come within a good price range as it was an invention of RepRap Project.

Moreover, Flashforge & Dremel are two awesome 3d printing machines after the Makerbot. Both are advanced and silent 3d printers with a lot of positive sides.

Bambu Lab is a newcomer in the 3d printing market. It drew the attention of the 3d print enthusiast at the maximum level for its print speed and low noise level. Overall, it’s an excellent piece of noiseless 3d printer currently available.

There are more critical factors that you should consider before choosing what is right for you as a silent 3d printing device.

So, let’s begin!

MakerBot Replicator Plus Silent 3d Printer | Best Overall

Makerbot Replicator is one of the fastest and quietest 3d printers with auto leveling available on market as of today. MakerBot comes with an Insanely large build plate and smart extruder mechanism. Also, Makerbot allows you to use their CloudPrint 2.0, a free 3d printing workflow mechanism with amazing productive flexibility.

This is the most updated 3d printer of the 21st Century having awesome print quality & speed.

The minimum layer height here would be 100 microns which works great with grief build surface.

What makes Makerbot stand out among other 3d printers

These are factors that helped Makerbot Replicator to stand out among other 3d printer brands available in the market

- Only MakerBot supports the most advanced cloud-based workflow automation (Cloudprint 2.0).

- Only MakerBot allows you to import native CAD files into slicers. We did not see such features in Dremel, Creality or Flashforge

- Makerbot’s dual extruding capacity was higher than the Creality.

- It does not require an enclosure like the others from Creality.

- Filament changing time was 7 seconds lesser than the Flashforge.

- Due to the build plate, MakerBot is very good at controlling Warping.

- Bed Levelling was 11% more accurate than the Anycubic printers.

Positive Sides of Makerbot Replicator Plus

- Compatible with CloudPrint 2.0 allows you to control print quality and queue management

- Allows you to print Native CAD files at a time on the single-build plate

- Comes with a larger build plate that helps to reduce the printing time

- Works great even at 85°F

- Environment friendly

- Also works with Aluminum, Polycarbonate, Polylactic Acid

- The consumable changing process is much easier

- A powerful stepper motor keeps the noise below 45 DB

- Extruder quality is better than the Creality

- Smart printing will allow you to keep it running overnight with zero risk of fire hazards

Negative sides of Makerbot Replicator Plus

- There is no heated build plate since it does not work with ABS

- Warranty may be limited to six months (subject to change as per the manufacturer)

3D Print Quality with MakerBot Replicator

We have done some experiments with this Makerbot silent 3d printer at our lab. Here are the results we had.

From the point of quality, the Makerbot is just amazing. The details it gives will blow your mind surely.

Here’s another 3d print by MakerBot Replicator Plus at our testing lab (Below).

Our purpose was to make a digital Texturing of CAD data interacting with ultra high resolution DLP is now generating part production surface quality that is beginning to synchronize with that of Injection Molding.

Hardware: MakerBot Replicator Plus High Speed Low Adhesion Membrane DLP

Material: PRO-BLK Production Grade Photoplastic

Build time: 2hr 36min

Wash Time: 5 min / 91% IPA (Batch Process)

Cure time: 90 min

Layer thickness: 30um

Here’s a printing quality comparison of MakerBot Replicator Plus & FlashForge

This is true that both the 3d printers are just great in printing quality. While comparing to the flash forge, we have seen that the printing speed of MakerBot is slightly higher. However, noise reduction was much more effective in Makerbot.

Besides, cloud print 2.0 adds an extra advantage for Makerbot users. They can easily customize the print quality settings without changing them into CAD. Such features were not available in Flashforge.

Here are some other MakerBot 3d prints to help your decision-making.

Check Price & Other Qualitative Issues of MakerBot Here>>>

How MakerBot Replicator is different from the other MakerBot 3d Printers?

This section clearly illustrates – how the Makerbot Replicator is different from the other MakerBot 3d Printers.

First of all, the Replicator Plus is great with noise reduction & works smoother than the previous MakerBot printers. all performance factors are far away from the MakerBot Sketch.

If we break down the user behavior, MakerBot Sketch is good for students or someone with normal usage. On the other hand, The replicator plus is for advanced users.

Another big advantage is that the Replicator plus can work with the MakerBot’s tough PLA filaments.

they have also worked with filament loading features to speed up the longer operation.

Explore 3d printers for Action Figure

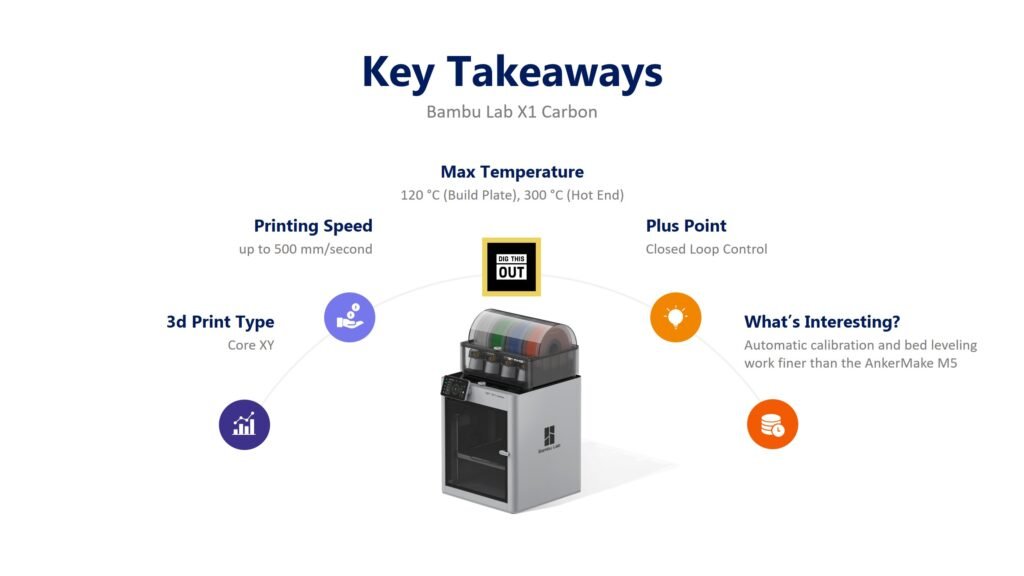

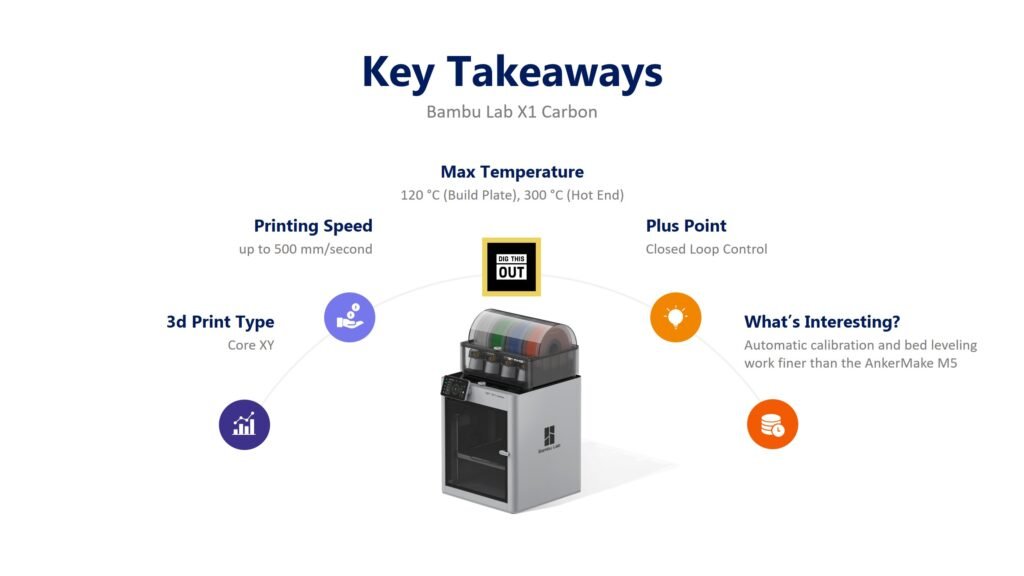

Bambu Lab X1 Carbon

Bambu Lab is a Core XY 3d printer with a maximum print speed of 500 mm per second. In terms of noise reduction, The Bambu X1 works great. The average noise level was 48.9 decibels for Bambu Lab with a minimum noise was 33.8 decibels.

The Best Part of Bambu Lab

Besides the low noise level, Bambu X1 Carbon is really fast. We tried 3d print experiments with this and the result was really amazing. That was the detailed review of Bambu Lab.

- The first experiment we did was a wave lamp.It is printed in PAHT and PAHT CF in 0.24mm layers and 5% infill settings. It took 7 hours and 23 minutes to get the 3d prints done with Bambu Lab X1 Carbon. The speed was amazing and the quality was awesome. There was no error noticed in the first layer and as well as within the middle.

- The second experiment we did with the Bambu lab was with a Blossom Vase. We used the Aqua Blue filament as an experiment and the print took only 1 hour and 31 minutes in total. We have used 2 walls and 5 bottom layers with layer height settings of 0.16mm.

- The third and final experiment was with the organic sculpture. We choose to go with a layer height of 0.2 mm and an infill percentage of 10%. We used silver PLA as our primary filament and the print took 9 hours to get done with an amazing end result.

Other Positive Sides of Bambu Lab X1 Carbon

- Transparent filament feeding hopper that holds 4 filament rolls

- No purge tower required

- All metal hot ends with a maximum nozzle temperature of 300 degrees Celcius

- No warping noticed

- 500 mm per second of print speed makes it amazing

- 32 mm^3/s max hot end flow helps in faster printing

- Cools quickly

- Comes with a premium enclosure

- The activated carbon filter helps protect us from toxic fumes

- Works with tough materials such as ABS & PETG

- Automatic calibration and bed leveling work finer than the AnkerMake M5

- 1080-pixel AI camera attached to the nozzle

- Cleaning and maintenance are a bit complex due to non-removable enclosures

- Controllable in smartphone

- The AMS saves you from incurring additional costs for dry box & humidity controller

- RFID tags detect Bambu labs filament automatically and adjust the slicer profiles accordingly (a value addition)

- Unfortunately larger filament rolls do not fit into the filament hopper. The same problem we have also noticed in AnkerMake M5. It could be a tick to purchase the Bambu Lab’s filaments (a good marketing trick)

- Hotend reaches 200 C in roughly 30 seconds which saves pre-heating lead time like other 3d printers. In 1 minute 20 seconds, the hot end reached a maximum temperature which is awesome.

- Heating takes a minute extra (2 minutes in total) to reach the maximum temperature of 120 C.

- The bed heats evenly which is a very good sign but there is no such flexibility of partial heating as Prusa XL.

Flashforge 3D printer Review | Best Direct Drive 3D Printer

Falshforge Adventure 4 is another best premium direct drive quiet 3D printers available in the market.

This is a super-efficient printer equipped with 45 DB Quiet printing technology. This device has a built-in camera for activity monitoring.

Also, the instant memory helps to restore the work during a power outage situation.

Overall, the high sensitive touch screen display, filament detector, and quick detachable nozzle give it an amazing premium appearance.

On top of everything, its super flat aluminum plate ensures the maximum flatness with the entire difference of less than 0.15 MM.

Our experts suggest that literally, anyone with no 3D printing experience can operate this 3D printing device just after watching their tutorial.

Printing quality

The 3D printing quality of Flashforge has always been attractive to customers. Especially the accuracy was excellent.

Here’s what we have got from the Flashforge silent 3D printer.

That was awesome isn’t that?

Positive Sides of this 3D Printer

This 3D Quiet printer has a built-in filament run-out detector system that helps to switch the filaments without sacrificing the quality of the 3D printing outputs.

Also, the memory backup function fights any uncertain power outage situation and that’s a great feature. Notable, such power and memory backup were not available in the Dremel 3D20 devices.

Furthermore, the connectivity features set ultimate freedom for you. You can easily connect this 3D printer in Wifi, Thumbs Drive, Ethernet, or with cloud printing.

No matter where you are, the 3D printing necessity will always be in first priority with this amazing quiet 3D printer.

Notably, the HEPA 13 automatic air filter system helps to filter the air within the medical grade.

Another great advantage would be its filament usage capacity.

Unlike other 3D printer brands, it allows you to use a full 1KG filament in a single project. Additionally, you can easily switch the filament nozzle faster than the Dremel 3D printers.

Negative Sides of this 3D printer

If the surface where you are keeping the 3D printer is unstable, there might be a bit of noise. However, you can easily fix this.

The 9 Point calibration might become boring as it takes a bit of time.

The built-in camera will not give you a detailed visualization, but an idea of what’s going on there.

Continuous layer shifting may provide you with an unsatisfactory 3D printing output. Make sure to work with the design cleverly.

Customers’ Testimonial

While doing the customers’ survey, we found some amazing notes.

One of the customers found the touch screen a little wonky while pressing the Wi-Fi password! Apart from that, no major complaint was received so far.

Mr. Shawn from South Dakota has especially mentioned that – he did not have any major issues while using 2 KGs of PLA on a single project.

The Bottom line

Undoubtedly, The Flashforge Adventure 4 3D Quiet Printer is capable of making its customer super happy!

It weighs 44 pounds which gives it a solid strength while controlling the noise arising from vibration. The stepper motor and the stepped driver work smoothly without any issues at all.

The build volume is slightly lower than the Dremel 3D45, but it does not have any drawbacks at all.

Flashforge printer comparison

let’s have a look at the Flashforge printer comparison.

Here’s our print output from Flashforge Adventure 4 and Adventure 4 lite.

FalshForge earlier had a good reputation for the adventure 3 series.

Currently, the Falshforge Adventure 4 3D has only its immediate version which is 4 Lite.

The main difference between both is the built-in camera, filament compatibility, Ethernet facility, and air purity.

The Flashforge 4 Lite does not have the built-in camera whereas version 4 had it.

The lite version does not support Ethernet, nor PETG compatibility.

Also, the lite version has a glass build plate whereas the flash forge 4 had a magnetic build plate.

Overall, the Flashforge lite can be a suitable choice who thinks about the budget first.

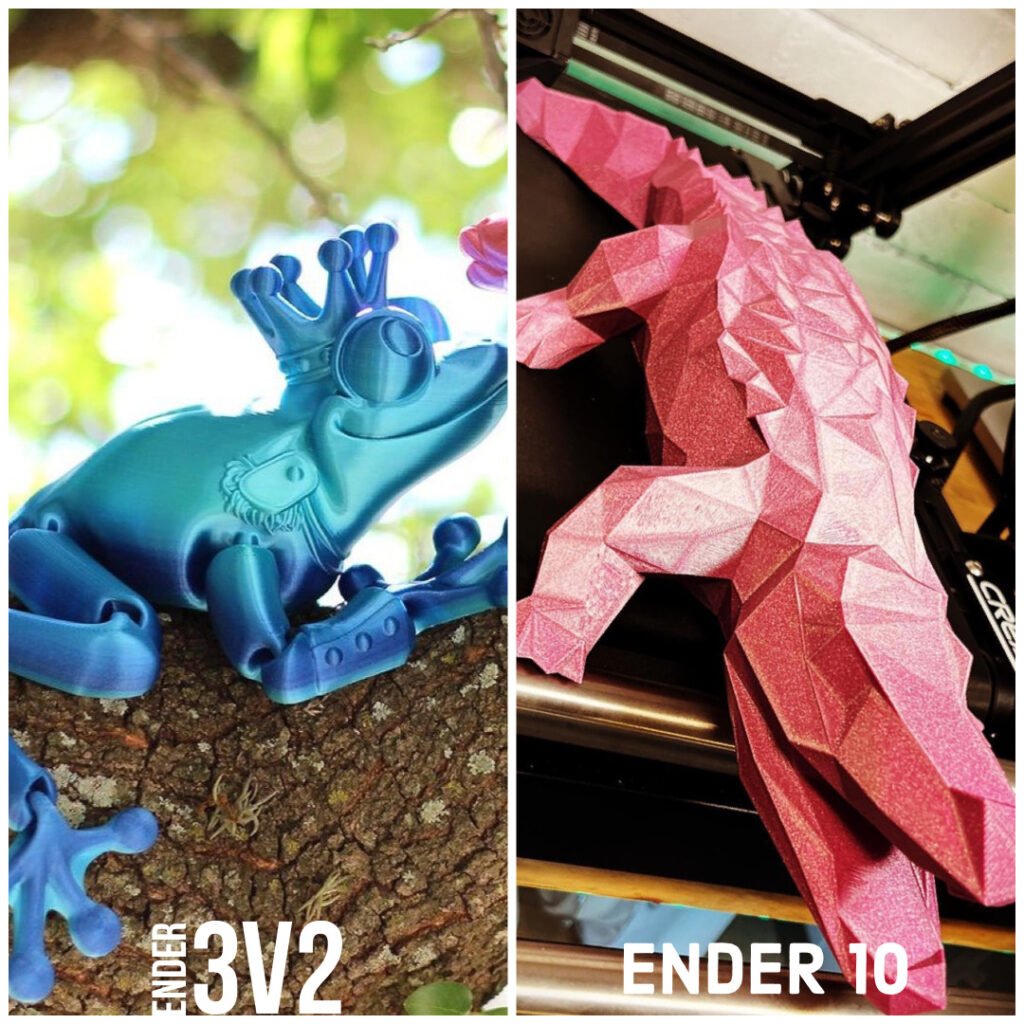

Creality Ender 3 V2 | Best Creality Printer

Creality Ender 3 V2 is the most rated Creality printer so far.

In the last 4 years, the company has sold more than 20,000 units of this Quiet 3D printer.

This 3D printer comes with a silent motherboard that keeps the noise below 50 DB. On top of that, the glass platform helps to warm up the base quickly for a quality 3D printing process.

We have also seen that the filament feed-in process is quicker than the Flashforge. Overall, this is a budget-friendly quiet 3D printer that you can buy.

We have tested the printing quality of this creality 3D printer.

Based on the print we have, you can easily mark this product as one of the finest quiet 3D printers. We have used their official software ‘slicer’, to deliver a design.

Here’s what we got!

Overall, we found the spider man so accurate with the design on Creality Ender 3 V2.

Positive Sides of Creality Ender 3

These are positive sides of having a reality ender 3.

- Unboxing & set-up time is within 15 minutes like Flashforge.

- Comes with a motherboard that is specially designed to reduce noise.

- No third-party software is needed to run this printer. Their own operating system ‘Slicer’ just works GREAT.

- Comes with all tools required for the assembly process. No need to buy anything else.

- The filament loading & filling process is faster than the Dremel 3D Printers.

- In case of a power outage, its automatic memory function starts the job again from the last point of production.

Negative sides of Creality Ender 3

These are the negative sides of the Creality ender 3 3D printer.

- Comes with only one basic filament. You need to order extra (The Flashforge 3045 comes with multiple filaments)

- Often becomes unavailable on Amazon! we tried to figure it out but, couldn’t know why!

Creality Ender 3D Printer Comparison

These are notable comparing factors of Creality Ender 3D printers. They have so many varieties so, you need to get a clear idea of what is your need.

Let’s start!

| Creality Ender 3 Pro | Creality Ender 3 V2 | Creality Ender 10 Series | |

| Build Volume | 220 x 220 x 250 mm | 220 x 220 x 250 mm | Bowden |

| User | Intermidiate | Intermidiate | Advanced |

| Wifi Enabled | Yes | Yes | Yes |

| Heated Build Plate | Yes | Yes | Yes |

| Silent Motor Driver | Yes | Yes | Yes |

| Belt Tensioner | No | Yes | Yes |

| Tool Drawer | No | Yes | Yes |

| Build Plate Material | Magnetic | Magnetic | Magnetic |

| 9 Point Lavelling | Yes | Yes | Yes |

| Print PLA | Yes | Yes | Yes |

| Print PETG, Nylon & ECO ABS | Yes | Yes | Yes |

| PETG Rolls Included | Yes | Yes | Yes |

| Extruder type | Bowden | Bowden | Bowden |

Almost all reality enders come with the same build volume which is 220 x 220 x 250 mm. This is slightly larger than the average mid-budget 3D printer available in the market.

Here’s a 3d print comparison of a Creality Ender 3 V2 and Ender 10.

You may learn about the best Ender 5 Plus Alternative here.

If you need a bigger 3D printer than this, we recommend you to check out the Creality Ender CR 10 series. It has a 300 x 300 x 400 mm build volume.

What about the assembly process?

Well, the official website said that the assembly might take an hour. However, during the testimonial collection, one of the Creality customers said that it took only 15 minutes to assemble.

Probably, that customer had previous experience.

Both the Creality Ender 3 series and the ender 10 series support PLA, PETG & ABS.

Also, the integrated screen is well functional for both the series but, the Creality 10 series have a different control screen that is better than the ender 3 V2.

Like all the premium 3d printers, all the Creality printers come with thermal runaway protection that helps save you from OVERHEATING in case of any malfunction.

Also, we have seen that the Ender 3 Pro series has a thicker central beam. It helps move the beam more efficiently than the other printers.

Dremel 3D Printer with Filaments Review | Best Ender 3 V2 Alternative

Overall, this 3D40 flex 3D printer by Dremel is a great innovation. This is the best ender 3 V2 Alternative in the market.

It comes with the amazing print quality and has a GREAT NOISE REDUCTION facility. The filaments help reduce the noise that giving it a much more impressive outlook compared to other similar products.

This 3D printer is not only super quiet; also, it allows you to print at both low and premium quality like the Creality ender 3 V2.

That means this is your choice to print at 0.3mm draft or even at 0.05 mm.

Moreover, the flex allows to remove prints more easily and customers are also happy about it.

It will be a great addition to your collection in case you are in need of prototyping something for concept approval.

Here’s a quick comparison of Dremel 3D45 & Falshforge 4 3D.

The comparison between Dremel 3D45 and Falshforge 4 3D will help you choose the right quiet printers.

3D Printing Quality

Here’s an example of 3D printing quality that we have got from Dremel 3D45. Let’s have a look

Positive Sides of this 3D Printer

These are the pros of this Dremel 3D40 Flex printer. We will categorize the limitations in a separate section followed by the positive sides.

- This is suitable for new and intermediate users.

- Unboxing and installation take around 10 minutes maximum.

- The build plate is made up of flexible steel that gives printing an advantage.

- Also allows you to print at an automated 6-point printing mechanism.

- Can also print PLA

- Filament rolls are included in the box.

- The enclosure helps keep the noise below to 50 DB.

- There will be no smell printing is in progress.

- Works in MAC, Windows, IOS & Chromebook.

- A colorful touch screen helps operate smoothly.

Negative sides of this 3D printer

These are considerable issues with this 3D printer. The points are not really a negative side if you are an intermediate user.

- The Stepper motor does not use a closed-loop system

- A heated belt plate is not available that may reduce less curling of the plastic.

User Testimonial

We have performed a user experience survey among 17 customers. Only 1 customer was unhappy about this 3D Printer due to having a jammed extruder.

However, 95% of the customers were satisfied after using this quiet 3D printer. There was no objection regarding hollow printing even.

One of the customers stated that –

He took 15 minutes to get this printer ready. He was amazed to see that there was pre built printing prototype in USB that allowed him to take one print quite easily in 30 minutes.

Regarding the noise level, he strictly quoted that this 3D printer is quiet and cannot deliver noise above 50 DB.

How this 3D printer differs from their previous Model?

We not only assessed this 3D printer. But also, done a comparison between the earlier versions of the same manufacturers.

This Dremel 3D40 is basically an upgraded version of their previous model 3D20. While the Dremel 3D20 address completely a new user, the 3D40 is suitable for both new and intermediate users.

The 3D20 does not support Wifi, nor the 9-point leveling. Also, 3D20’s build plate is made up of acrylic which limits the 3D printing facility to some extent.

However, Dremel holds an upgraded version of its 3D40 printer, which is 3D45.

Here’s a quick summary:

Here’s the Key Difference between Dremel 3D40 & 3D45

Both the printers have the same printing volume and wifi supported. The key difference that 3D45 have is a glass build plate material.

Here’s a 3D print comparison of Dremel 3D40 and 3D45

Furthermore, the Dremel 3D45 also contains a heated belt plate and is capable of printing PETG, Nylon, and ECO ABS.

What’s the Bottom-line?

If you are an intermediate user and looking for a quiet 3D printer under 100 then the Dremel 3D40 would be a great option.

If you are looking for an advanced 3D Printer with lots of professional features, then the Dremel 3D50 is what you are looking for.

However, the Dremel 3D50 is a good quiet 3D printer under 2000.

Anycubic Vyper Silent 3D Printer

Anycubic is another silent 3d printer with amazing features. Its double gear extrusion system heats up to 260℃. Noise is also considerably lower than the Creality Printers.

Print speed is below 100 mm/s, which is fairly good in the market. Another awesome feature is its double FAN system. Two fans dispense the heat in different directions which helps to reduce the temperature.

Besides the normal features such as memory restoration after the power outage, the Anycubic printers can also complete the 3d printing job with zero filament wastage. It will start the job exactly where it was left.

Check Price and Customer Reviews here>>>

Anycubic Vis very efficient in quick installing and dissembling. The belt adjustment mode provides more accuracy of 3d printing by adjusting the tension of the X/Y.

Moreover, the magnetic platform along with its scratch-resistant surface makes it more elegant.

Positive Sides of Anycubic Vyper

- Magnetic build plate

- Auto Bed Leveling with extra accuracy

- Duel gear extrusion system

- Colorful touch screen for smoother operation

- Modular print head along with printing light

- 4.3-inch LED control panel

- Cooling fan’s performance was great

Negative Sides

- Some of the users found the Anycubic Vyper not connecting with the Mac as easily as Windows.

- Does not come with an enclosure

- Does not offer glass build plate

- Bed temperature is bit lower than the Kobra Max that may cause Warping

Printing Quality of Anycubic Vyper

These are the 3d print quality we had with Anycubic Vyper

In our opinion, Flashforge, Dremel, and MakerBot give better output than the Anycubic Vyper. Even the Anycubicclaims that there will be no wastage in case of a power outage, we have seen the process deteriorates sometimes.

The noise-controlling feature was not as active as the MakerBot. However, the build plate is very good than Makerbot’s one.

No complaint about its bed leveling. Everything was fine.

Anycubic Kobra Max could be a better choice

We have separately published a detailed comparison between Anycubic Vyper and Kobra max.

From that, you can easily conclude that the Kobra max is a better deal than the Anycubic Vyper because of the following reason.

- There is only a USD 100 difference between Vyper & Kobra Max

- Kobra Max offers a comparably larger build plate than the Vyper

- Kobra Max comes with a Glass build plate whereas the Vyper offers a Magnetic build plate

- Kobra Max is heavier than the Vyper

Read this piece of an article if you are looking to get a 3d printer mainly to make action figures.

Creality VS Flashforge

Let’s have a comprehensive comparison of Creality VS Flashforge.

| Flashforge 4 3D | Creality Ender 3 V2 | |

| Build Volume | (8.7 x 7.9 x 9.8 IN) | (11.8 x 11.8 x 15.75 IN) |

| User | Intermediate & Advanced | Intermidiate |

| Wifi Enabled | Yes | Yes |

| Heated Build Plate | Yes | Yes |

| Silent Motor Driver | Yes | Yes |

| Belt Tensioner | Yes | Yes |

| Tool Drawer | No | Yes |

| Build Plate Material | Magnetic | Magnetic |

| 9 Point Lavelling | Yes | Yes |

| Print PLA | Yes | Yes |

| Print PETG, Nylon & ECO ABS | Yes | Yes |

| Filament rolls included | Yes | Yes |

| PETG Rolls Included | Yes | Yes |

| Extruder type | IDEX | Bowden |

Both the 3d printers have super performance for intermediate users.

Flashforge comes with an IDEX extruder and the Creality with the Bowden.

Here’s a 3d print comparison of Creality Vs Flashforge

An extruder helps to melt and distribute the plastic filaments of a 3D printer.

IDEX extruder allows moving two print heads separately and independently. It directly contributes to the 3D printing accuracy and quality. Similarly, the Bowden extruder also helps to build a large 3D volume with more accurate movements.

Both the Creality and Flashforge 3D printers are WIFI enabled with a silent motor driver and heated build plate.

However, the tool drawer is not available on Flashforge.

Both printers have 9 point leveling mechanism and support PETG, PLA, and ABS.

However, both of the printers come with a few filaments and you need to order more depending on your requirement and color preference.

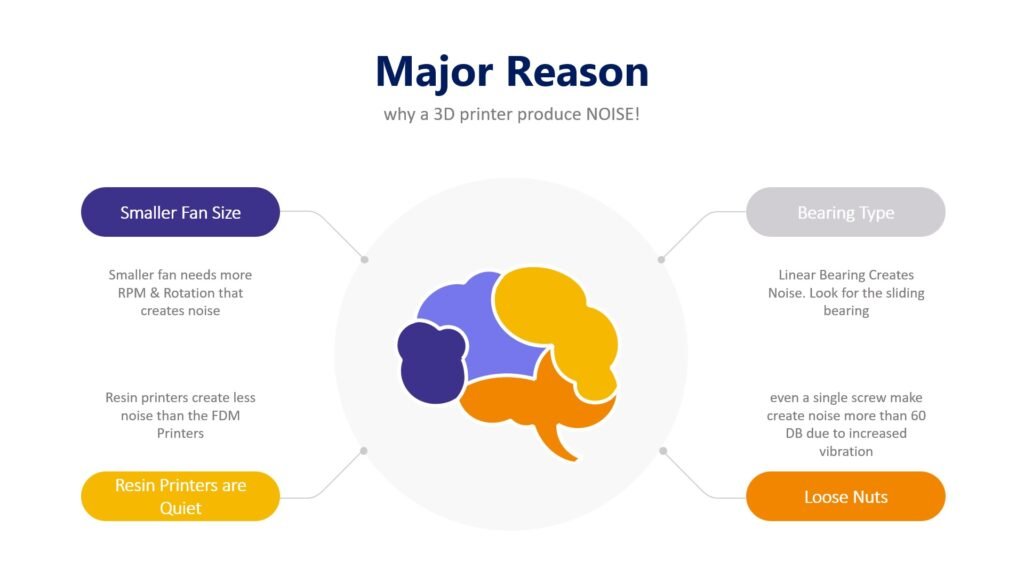

What makes a 3D printer noisy?

A 3D printer is a combination of different types of machines. Not every part of that creates noise except a few.

Noises mainly come from bearings, linear rail carriages, fans, motors, and other nuts and belts.

However, if you are reading this guide, you will be ready in a minute to identify the ideal quiet 3D printer for you.

Here’s another guide on 3d printer noise…

Quiet 3D Printer buying guide

Here’s a list.

The list includes different parts & quality factors that make a 3D printer noiseless. We assume that you will get to know each of the things separately and choose the right 3D printer for you that is quiet.

FDM Technology

Most of the prominent 3D printer manufacturers use FDM technology. The technology mainly guides different layers of filament to reduce the noise level.

Again, put this term on your checklist before buying any 3D printer, especially if you are looking for a quieter one.

Components are in use

The main thing you need to notice here is the tolerance level of a 3D printer.

Let’s say, a cheaper printer creates more noise just because of their poor tolerance level. Since the printing technology creates a lot of vibrations, it needs to put heavier 3D printing components to get rid of the noise.

For example, a 3D printer under 1000 comes with an above-average configuration and bit quieter than the cheaper versions.

However, you might choose this 3D printer if your budget supports the best quiet device.

Learn more about PBT Material.

Fan Size

The size of the fan really matters when considering buying a noiseless 3D printer.

For instance, a smaller fan will have a bigger RPM while in operation. On the other hand, higher RPM creates more vibration and noise.

So, make sure to look at the fan size or its RPM before buying.

Bearing Type

As mentioned above, linear bearings are one of the components that create noise from a 3D printer. But, if you are wondering to have a quieter 3D printer then look for the sliding linear bearings.

A study suggests that the sliding bearings create less noise compared to the recirculating ball bearings.

Importance of Maintenance

Besides all of the important parts, maintenance plays a vital role. Sometimes dust gets inside and creates noise while extrusion is working.

You need to be equally ready and equipped with a promise for regular maintenance. Let’s say, if you can lubricate regularly, the noise level will be lower and the 3D printer will always remain a quiet device.

Learn more about whether you can keep a 3d printer on Garage.

Get to know about different 3d Printer technologies?

Earlier, we mentioned FDM technology that uses filaments to reduce the noise level.

However, there is a better version than that of FDM 3D printers.

Well, what’s that?

The research found that the Stereolithography or SLA Resin 3D printers produce comparably less noise than the FDM 3D printers. The reason is the increased number of moving parts used inside.

Additionally, Resin 3D printers consist of a single fan while the FDM printers have noisy stepper motors, bearings, and fans.

Apart from that, FDM 3D printers do not contain fumes like the Resin 3D printers. That is why the FDM printers tend to be louder than the SLA resin 3D printers.

So, what is the conclusion?

Should you consider buying a Resin printer or an FDM printer?

Well, if your preference is NOISE REDUCTION then the best quiet 3D printer would be a Resin 3D printer undoubtedly.

Here’s a breakdown of 3d printing technology:

| Type | FFF | SLA | SLS | Piston |

| Material | Plastic | Liquid Resin | Nylon Powder | Anything |

| Durability | Depends | Low | High | Depends |

| Presision | 0.1 mm or less | High | Good | N/A |

| Post Processing | Easy | Tough | Tough | Tough |

| Freedom of Forms | No | Limited | Yes | Very Limited |

Fused Filament Fabrication (FFF)

Through fused filament fabrication (FFF), you can create a low-cost model. FFF 3d printer mainly uses different types of plastic rolls with 2 mm or less precision. The post-processing is super easy and also the unit cost is very low.

Most of the 3d printers use the FFF method with a variety of materials. Notably, ABS is good for legos or car parts and PLA is best for solid modeling.

Stereolithography (SLA)

SLA 3d printers are good for creating prototypes. It uses liquid resin with high precision. However, the durability is low with limited heat resistance. Normally, the unit cost becomes higher due to the material type.

Selective Leser Sintering (SLS)

SLS printers use Nylon to create 3d objects. This additive manufacturing technique uses efficient laser power to create durable 3d models. However, blasting may be needed to remove the extra powder.

Syringe-Based System Piston

Through the piston, you can literally enter anything. You can use chocolate or epoxy resin to create the 3d model. However, the freedom of form is limited in piston printers due to use of material and the variation of quality it produces.

How to make 3D printers QUITTER?

You might be wondering to know how to make your 3D printer quitter!

Here’s a list of components, tricks, and strategies that will surely help you in making a 3D printer quitter.

So, let’s start!

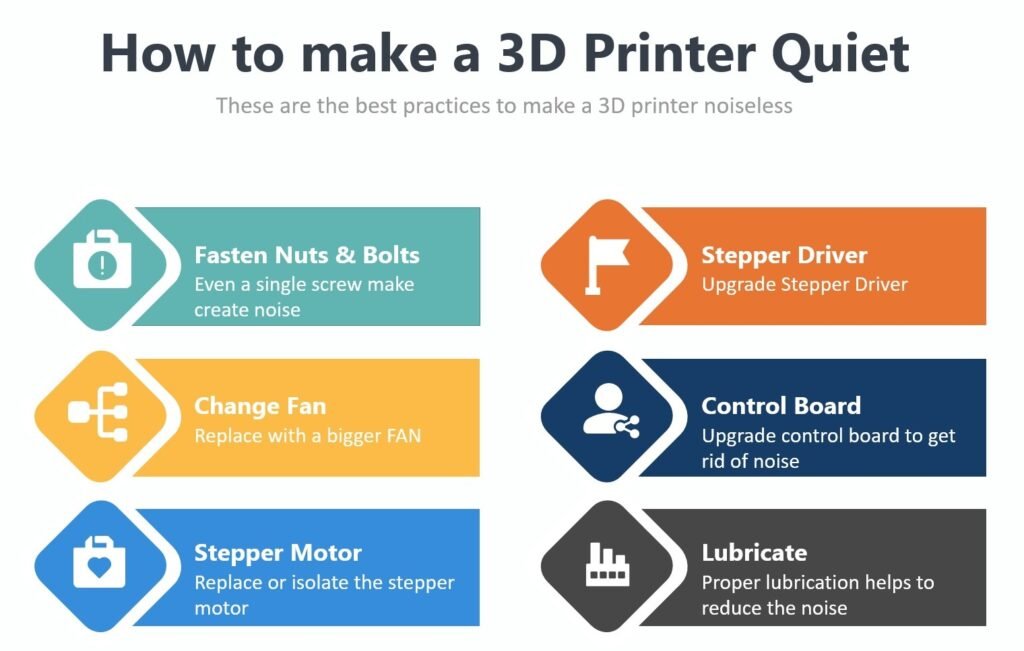

Fasten bolts, nuts, screws and clamps

Seems silly, but it’s true.

You need to make sure that you have fastened all the available screws, nuts, clamps, and bolts before making your first 3D print.

Remember, even a single screw make creates noise of more than 60 DB due to increased vibration.

Also, make sure to check it regularly. Because vibration may loosen up the nuts or screws suddenly.

We recommend you use a good thread locker while fastening the threads.

However, you should not use the wrong thread locker.

If you do so, you might not be able to re-open the threads in the future. That’s an alarming issue and we request you to choose the right thread locker before applying.

Change the Fan to reduce noise

Due to the functionality, a 3D printer requires many fans to cool down the motor, heat sinks, and other parts. There’s a chance that you can easily replace the louder fan with a silent one to make the 3D printer quiet.

However, we didn’t see any silent fan existing in the 3D printers mainly due to the following reasons.

Firstly, a 3D printer cannot ensure a place for a bigger fan. Especially, there are fans within 30*30mm to 60*60mm.

As a result, the smaller fans rotate more frequently with higher RPM to pass enough hot air.

And, you already know that the higher RPM creates more noise.

Secondly, 3D printer manufacturers often use a smaller fan to bring their own costs down. Surely this is a profitability trick but, it is equally good that the manufacturers heavily focus on printing quality rather than the noise.

We assume that the Quiet printer is becoming a new demand from 2022. So, manufacturers will surely do research on that.

Overall, people often look for print volume and print quality. It results from the manufacturers keeping less focus on the noise level.

Replace or Isolate the Stepper motor

The Stepper motor, being the most important part of the 3d Printer may cause Noise. It helps move the extruder or by building a platform for X & Y-axis.

However, the stepper motor is a silent device but, it can create noise.

Let me explain, how!

When vibration gets through the frame, it creates other components to resonate. Also, the resonation may affect the cabinet, table, or the place where the printer is set.

So, the stepper motor can pass the vibration, as well as the noise!

To solve this problem, you can isolate the stepper motor or replace it for a better quiet 3D printing performance.

Upgrade Stepper Drivers

The Stepper dripper in a 3D printer is mainly responsible to control the power delivered to the electromagnetic coils.

We have seen that most stepper drivers move by 1/16 micro-stepping. That means, it takes a lot of small steps to complete a task.

As a result, starting and stopping frequently creates a lot of vibration and noise.

To solve this, you can consider replacing the stepper driver with a one-step higher micro-stepping.

Upgrade Control Board

The Control board is responsible to handle all the logic & programming of a 3D printer.

There is a possibility that your 3D printer might come with unchangeable stepper drivers. In that case, you may need to change the control board to make a quiet 3D printer.

If your 3D printer is a low-budget one, we suggest you to upgrade the control board that uses Trinamic’s TMC2225 stepper drivers. It helps to reduce the vibration and so noise.

Use Filament Cleaner

Filament cleaner helps to stop outside dust while feeding is in process. If the filament is not clean, then the dust may go inside into the extruder and create noise.

Lubricate Rails & Bearings

If you can lubricate the rails and bearings of your 3D printer then it will become quiet. We all know that lubrication helps reduce noise.

However, you need to look at these steps before that.

Make sure to wipe out the previous lubricants. If it seems difficult, try using a good degreaser.

Then apply a small amount of new lubricant to the bearings and nut.

Move slowly and lubricate. It will help mitigate excess lubrication.

Install Metal Enclosure

A metal enclosure helps to block the noise at the source. Also, such an enclosure helps to restrict the fire in case of any incident.

Change the surface

A 3d printer makes vibration that creates noise. Sometimes, an uneven surface may cause a higher vibration.

We suggest you change the surface or apply a soft mat underneath the 3D printer. Try keeping it on a flat and steady surface so that the stepper motor works accurately with low noise.

Overall, the noise that comes from a 3D printer is about 50 – 60 DB. Also, most noise arrives from the fan built-in. We assume that you have read our in-depth guidelines clearly and will apply them as suggested.

(Information Source)

Frequently Asked Question

This section addresses some frequently asked questions about 3d printer noise and their respective performance

How long can you pause a 3d printer?

You can pause a 3d printer as long as you can until the bed and the extruder position are not changed. However, there are some risks of a long time pausing such as the printer might not start working from where it left the work or, there could be a clogged extruder that may interrupt the rest tasks. It is always suggested to have sufficient filament & extra nozzle for immediate replacements.

How can I reduce 3d print costs?

These are the ways by which you can reduce 3d print costs:

Reduce infill percentage

Remove support filament

Make hollow drawing

Take advantage of batch processing

Make 3d model designs by professional CAD designers

Upgrade 3d printer rather than replacing & many more here.

Is 3d print fume toxic?

Yes, 3d print fumes are toxic and they produce VOCs & UFPs. However, the toxicity may vary depending on the filament you are using. For instance, Nylon was the most toxic in terms of producing harmful fumes and PLA is the least toxic. You should ensure that there is proper ventilation & a HEPA-certified air filter is activated to reduce the impact of VOCs. We always recommend using an enclosure & install a carbon filter to reduce the impact. Read our comprehensive guidelines here.

How to make 3d prints waterproof?

Waterproofing 3d prints are a bit technical. To do this, you need to be slow and smart. For instance, a slow extrusion makes the prints waterproof by reducing the bubble within the layers. Furthermore, increasing the infill percentage & working with a smaller nozzle also makes the print waterproof. Apart from these, some post-processing techniques such as epoxy coating and ACETONE smoothing can make the 3d prints waterproof. For more, follow this article.

What if the FIlament makes a Jamming Noise?

If there is any jamming noise coming from the filament there are some immediate actions you may prefer. If it occurs due to overheating the filament, stop 3d printer immediately until it cools down by itself. The noise may also occur if the hot end temperature is significantly low. In that case, you may increase the temperature and work again. Make sure that the nozzle is so close to the bed. It can also such noise.

For a better understanding, read our latest article on 3d Printing Noise & Their Fixes.

How to make 3d prints durable?

Firstly, the quality of a 3d printer will surely contribute to enhancing the durability of the 3d prints. However, there are some tricks that may help a lot. These are:

Use stronger filament

Increase infill density

Change extrusion direction by ignoring the flat direction

Implement proper flow rate

Try annealing 3 printer parts

And. try electroplating the 3d prints

Read our in-depth guidelines for increasing the 3d prints’ durability.

Are 3d printers’ nozzles universal?

The nozzle is a part of a 3d printer mainly responsible to dispatch melted filament on the print bed. Nozzles are not universal, and neither are interchangeable. The nozzle comes with a different diameter and could also make of a different material.

If you need to change the nozzle, look closely at the 3d printer’s manual about the specification.

These are the situation where you may need to change the nozzle:

If you want a faster print through a wider nozzle

If there’s a better one

If the nozzle is clogged with filament and you cannot clean

If you want to print food products the stainless steel nozzle would come into assistance

Can 3d Printer print metal?

Yes, 3d printers can print metal but industrial metal printers can do the job. The printers we featured in this article cannot print metal. Usually, a metal 3d printer uses power material to make the 3d model. But, this additive technology is not cost-efficient for advanced or intermediate users.

Can 3d Printer print Silicone?

Yes, they can. Because of the high viscosity, it took a lot of time to develop a 3d printer that can actually print silicone by the layer-by-layer approach. However, thermal stability is the primary requirement to work with silicone. Usually, it takes between 80°C to 200°C temperature to ensure a smoother 3d printing experience with silicone.

Can 3d printer resin cause cancer?

Directly working with resin can not cause cancer immediately. However, there is the possibility that the 3d printing fumes can be toxic and the VOCs can cause long-term health effects.

We have already published an article covering this area.

Does a 3d printer use a lot of electricity?

3d printer works with temperature so it consumes electricity. Normally, a mid-budget 3d printer takes around 50-150 Watts of electricity. However, some printers would need much electricity capacity, especially working with large 3d models or tough filaments.

As per the recent US average electricity rate, an hour of 3d printing operation would cost you around $1.3 cents.

This is not so much!

There are some ways to minimize the electricity consumption of 3d printers. You can consider building an enclosure or using a printer that can actually print too many models at the same with the same hot-end extrusion.

You can also try installing a heated build plate and reducing the print time with a change in infill percentage or wall thickness.

Conclusion

Choosing the Quiet 3D printer under 1000 is not a tough deal. It is important for you to understand the function of each of the separate components. We hope that our review and the buying guide were useful.

An excellent piece of write up. It’s so in depth and clearly written. I liked the way that they have shown the performance of each 3D printers. Great job